Unveiling the Enigma: How Generators Create Electricity

Imagine a world without electricity—a world where darkness reigns after sunset, and essential services like hospitals and communication networks grind to a halt. Generators, those unassuming powerhouses, play a crucial role in preventing such a scenario, providing a reliable backup power source during outages and powering essential appliances in remote areas.

But how do these machines actually work their magic? How do they transform mechanical energy into the electrical energy that powers our lives? Let's delve into the fascinating world of generators to uncover the secrets behind their operation.

The Core Principle: Electromagnetic Induction

At the heart of every generator lies the principle of electromagnetic induction, a phenomenon discovered by the brilliant scientist Michael Faraday. This principle states that when an electrical conductor, such as a wire, moves through a magnetic field, a voltage difference is induced across the conductor. This voltage difference, in turn, drives the flow of electric charges, creating the electrical current that powers our devices.

Think of it like a river flowing downhill. The magnetic field represents the slope, and the conductor moving through it is like a boat navigating the river. The slope creates a force that pushes the boat downhill, just as the magnetic field induces a force that pushes the electric charges through the conductor. This force is what creates the electrical current.

Dissecting the Generator: Essential Components

A typical generator comprises several key components that work together to convert mechanical energy into electricity. Let's break down these components and explore their roles in this intricate process.

1. The Engine: The Powerhouse

The engine is the driving force behind the generator, providing the mechanical energy that powers the generator's internal workings. These engines can be powered by various fuels, such as gasoline, diesel, propane, or natural gas, and their size determines the generator's maximum power output.

Think of the engine like a muscle, providing the strength to spin the generator's internal components. The type of fuel used, like gasoline or diesel, determines the muscle's type and its ability to perform different tasks.

2. The Alternator: The Electricity Factory

The alternator, also known as the genhead, is the heart of the generator, responsible for converting the mechanical energy from the engine into electrical energy. It consists of two main components:

- Stator: The stationary component with coils of wire wound around an iron core. These coils act as the conductor through which the electrical current flows.

- Rotor/Armature: The rotating component that generates a magnetic field. This field is what interacts with the stator's coils to induce an electrical current.

The rotor can generate its magnetic field in three ways:

- Induction (Brushless Alternators): Common in larger generators, this method uses a magnetic field created by the stator's own current flow to induce a current in the rotor, eliminating the need for brushes.

- Permanent Magnets: Found in smaller units, these generators rely on permanent magnets embedded in the rotor to generate the magnetic field.

- Exciter: A small DC source that energizes the rotor, providing the magnetic field necessary for current generation.

The interaction between the rotor's magnetic field and the stator's coils is what ultimately creates the electrical current output of the generator. It's like a dance between magnetic forces, where the rotor leads and the stator follows, generating a continuous flow of electrical energy.

3. The Fuel System: Supplying the Power Source

The fuel system ensures a continuous supply of fuel to the engine, allowing it to generate the mechanical energy needed to power the alternator. This system typically includes a fuel tank, pipe connections, a ventilation pipe, an overflow connection, a fuel pump, a fuel water separator/fuel filter, and a fuel injector.

Think of the fuel system like a network of roads delivering fuel from a storage depot to a factory. Each component plays a crucial role in ensuring that the engine receives a constant supply of fuel, allowing it to operate smoothly and provide the necessary mechanical energy.

4. The Voltage Regulator: Maintaining Stability

The voltage regulator is a critical component that controls the generator's output voltage, ensuring that it remains within a safe and stable range for powering electrical devices. It works by converting a portion of the generator's AC output into DC current. This DC current is then used to energize windings in the generator's rotor, increasing the magnetic field strength and ultimately regulating the generator's output voltage.

The voltage regulator acts like a traffic controller, monitoring the flow of electricity and adjusting the generator's output to ensure that the voltage remains within acceptable limits. This prevents voltage fluctuations that can damage electrical devices or disrupt their functionality.

5. The Cooling & Exhaust System: Managing Heat and Fumes

The cooling and exhaust system are essential for managing the heat and fumes generated by the engine. The cooling system uses a radiator and fan to dissipate heat from the engine, preventing overheating and ensuring smooth operation. The exhaust system directs exhaust fumes outdoors, away from doors and windows, to prevent carbon monoxide poisoning.

Think of the cooling and exhaust system like a ventilation system for the engine, keeping it cool and removing harmful fumes to prevent health risks. The cooling system ensures the engine doesn't overheat, while the exhaust system prevents dangerous gases from accumulating.

6. The Lubricating System: Keeping Things Smooth

The lubricating system ensures smooth operation of the engine's moving parts by providing a layer of protective oil. This system includes a lubricating oil reservoir, a pump, and filters. The oil level should be checked regularly and the oil changed periodically to maintain optimal performance.

The lubricating system acts like a shield for the engine's moving parts, reducing friction and wear. Just like how oil helps a car's engine run smoothly, the lubricating system ensures that the generator's engine operates efficiently and reliably.

7. The Battery Charger: Powering the Start-Up

The battery charger maintains the generator's battery charge for starting purposes. It provides a precise float voltage to keep the battery charged without overcharging, ensuring that the generator can start reliably when needed.

The battery charger acts like a life support system for the generator's battery, ensuring that it has enough power to start the engine when needed. This is crucial for providing backup power during outages, as a dead battery would render the generator useless.

8. The Control Panel: The User Interface

The control panel provides a user interface for the generator, allowing users to monitor its performance and control its operation. It typically includes electric start and shut-down controls, engine gauges, generator gauges, and other controls for adjusting settings like phase selector, frequency switch, and engine control.

The control panel acts like the dashboard of a car, providing information about the generator's operation and allowing users to adjust settings and control its functions. This makes it easy to monitor the generator's performance and ensure its safe and efficient operation.

9. The Main Assembly/Frame: The Foundation

The main assembly/frame provides structural support and grounding for the generator. It ensures that the generator remains stable and secure, protecting its components from damage and ensuring safe operation.

Think of the frame as the skeleton of the generator, providing the structural integrity and stability needed for its operation. It keeps all the components securely in place, allowing the generator to function without issues.

Harnessing the Power: A Symphony of Mechanics

In essence, a generator is a marvel of engineering, seamlessly integrating mechanical and electrical principles to produce electricity. From the engine's mechanical energy to the alternator's magnetic field and the voltage regulator's precise control, each component plays a crucial role in this intricate process.

Understanding the workings of a generator allows us to appreciate the ingenuity behind its design and the vital role it plays in our lives. It's a testament to the power of human innovation, ensuring that we have access to electricity even in the face of challenges and outages.

How does a generator create electricity?

What is the basic principle behind electricity generation?

Electricity is generated by converting other forms of energy, primarily through the principle of electromagnetic induction, discovered by Michael Faraday. This means moving an electrical conductor (like a wire) through a magnetic field creates a voltage difference that drives the flow of electric charges. This flow becomes the electrical current output of the generator.

How do generators work?

Generators use mechanical energy to power the movement of a conductor within a magnetic field, thereby inducing an electric current. This mechanical energy can come from various sources, including:

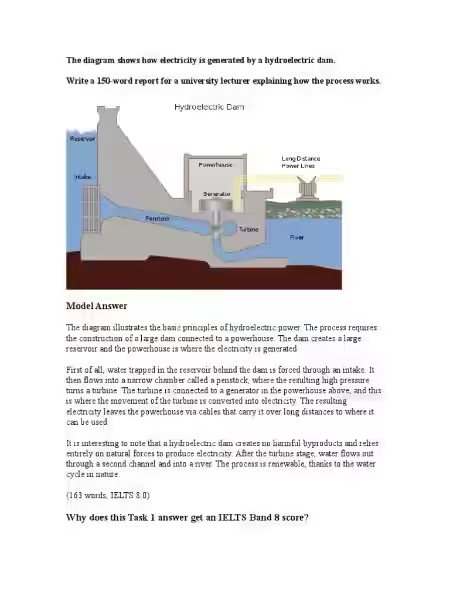

* Turbines: These are driven by moving fluids like water, steam, gas, or air, which in turn drive generators.

* Internal Combustion Engines: These are widely used for mobile power and emergency backup and can operate on various fuels.

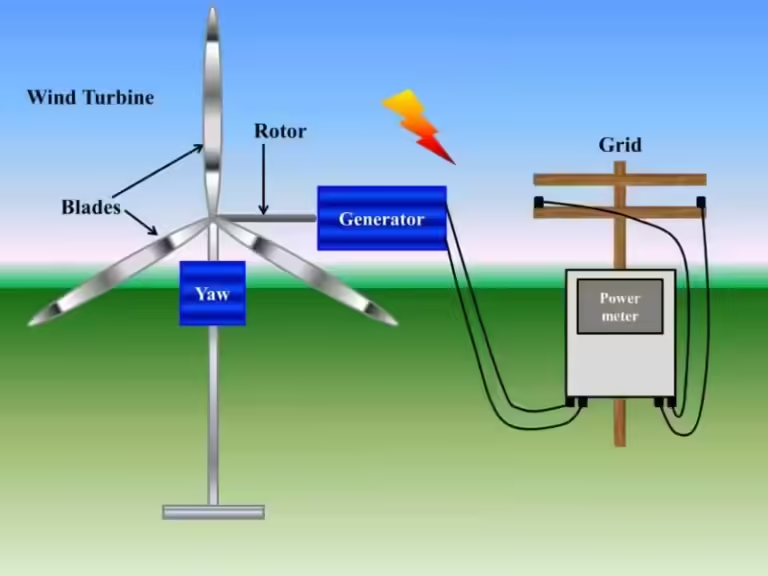

* Wind Turbines: These harness wind energy to spin blades, converting it into mechanical energy for electricity generation.

What are the main components of a generator?

Most generators consist of these key components:

- Engine: Provides mechanical energy to power the generator.

- Alternator (GenHead): Converts mechanical energy into electrical energy.

- Fuel System: Stores and delivers fuel to the engine.

- Voltage Regulator: Controls the generator's output voltage.

- Cooling & Exhaust System: Manages heat and fumes generated by the engine.

- Lubricating System: Ensures smooth operation of moving parts.

- Battery Charger: Maintains the generator's battery charge.

- Control Panel: Provides user interface for the generator.

- Main Assembly/Frame: Provides structural support and grounding.